1000l Essential Oil Distillation Extraction Equipment

1000L Essential Oil Distiller Product Introduction

Essential oil steam distillation advanced and Continuously improving. We had specialized in essential oil extracting technology and equipment for more than 30 years, serviced thousands of customers all over the world. we hope to bring customers extraordinary experience and sincerely hope to serve you.

Advantages Of 1000l Essential Oil Extraction Equipment

- Advance technology: automatic operation, more convenient and safer when running operation;

- Saving space: needn’t large hoisting equipment for installation and operation;

- High efficiency. Pressure device in the kettle can shorten the distillation time,4-6 hours finish one batch;

- Easy operation. One person can operate this machine easily.

|

Accessories

|

Parameter

|

|

|

Distillation kettle volume L

|

1000

|

|

|

Kettle inside design pressure Mpa

|

0.09

|

|

|

Heating area ㎡

|

3

|

|

|

Condenser system ㎡ (condenser +cooler)

|

5

|

|

|

Feed port diameter(mm)

|

400

|

|

|

Oil-water separator(fermentor)L

|

60

|

|

|

Equipment floor area(mm)

|

Length

|

7500

|

|

Width

|

2600

|

|

|

Height

|

5500

|

|

|

Evaporation capacity (kg/h)

|

150

|

|

Technical Parameters of 1000l Essential Oil Distillation Equipment

|

Distillation kettle

|

Effective volume: 1000L, using high-pressure steam through heating.

Inside: working pressure: normal pressure;design temperature:120℃,work temperature≤100℃.Working medium:water; Upper oval headδ=6mm/S30408,Cylinder δ=6mm/S30408. Sewage valve: DN200, |

|

Demister

|

Size Φ300×750,δ=3mm/S30408, Demister inside has baffle, The top of the demister is set to the quick opening hole. Demister to facilitate cleaning. Meet the GMP requirements.

|

|

Condenser

|

vertical coil condenser

|

|

Steam distributor

|

Three-dimensional steam distributor, more thorough steam through

the material, improve the yield and quality of essential oils. |

|

Oil-water separator

|

Stainless steel tank, Glass as the cup, Dedicated oil-water separator. Volume: 100L,size δ=3mm/S30408.

|

|

Double filter

|

Stainless steel tank, Glass as the cup, Dedicated oil-water separator. Volume: 100L,size δ=3mm/S30408.

|

Application Of Essential Oil Distillation Equipment:

This essential oil distillation equipment is popular, famous, advanced and of top quality in the production of Chinese medicines, health products, biological drugs, cosmetics, and food. This essential oil Distill equipment uses technology and chemical separation, can extract plant components efficiently by steam distillation, have a good effect in collecting essential oil from plants.

| Flowers | Rose; jasmine; lavender; chamomile; ylang-ylang; geranium; neroli; clary sage;achillea millefolium; osmanthus; peony; marigold;laurel; |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniperberry; cypress; pine needles;spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedarwood; rosewood; agarwood; Birch; holly; camphor;melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; Amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine. |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper;capsicum; fennel. |

| Raw material | Oil Yield (%) | Raw material | Oil Yield (%) |

| Gaultheria procumbens | 0.66 | Eugenia caryophylatta | 14-21 |

| Achillea millefolium | 0.007-0.50 | Coriandrum Officinalis | 1 |

| Cymbopogon nardus | 2.0-4.0 | Anetlnun graveolens | 2.5-4 |

| Pimenta d ica | 4.5 | Eucalyptus spp | 1.0-7.0 |

| Angelica seed | 0.3-1.0 | Foeniculum vulgare | 4 .0-6.0 |

| Angelica plant | 0.6-1.5 | Boswellia carterii | 3.5-6.0 |

| Amica montana plant | 1 | Pelargonium graveolens | 0.3-2.0 |

| Amica Montana flower | 1 | Juniperus communis | 1.5 |

| arusum | 1.5-4 | Lavendula angustifolia | 0.5-1.0 |

| Ocimum basilicum | 0.5-1.5 | Citrus limonum | 2 |

| Laurel nobilus | 3 | Melissa offivinalis | 0.015 |

| Melaleuca leucadendron | 1 | Origarunn majorana | 0.9 |

| Cinnamomum camphora | 2 | Myristica fragrans | 15-25 |

| Carum carvi | 3.2-7.4 | Citrus spp | 1.5-2.0 |

| Cinnamomum cassia | 1.5 | Origanum vulgare | 1.2 |

| Santalum album | 2-4.5 | Petroselinum crispum | 6 |

| Matricaria chamomilla | 0.3-1 | Mentha piperita | 1.0-2.5 |

| Anthemis nobilis | 0.3-1 | Pinus spp | 0.5-3.0 |

| Cinnamomum zeylanicum | 0.1 | Rosa spp | 0.04 |

| Salvia sclarea | 0.1-0.34 | Rosmarinus officinalis | 0.5-2.0 |

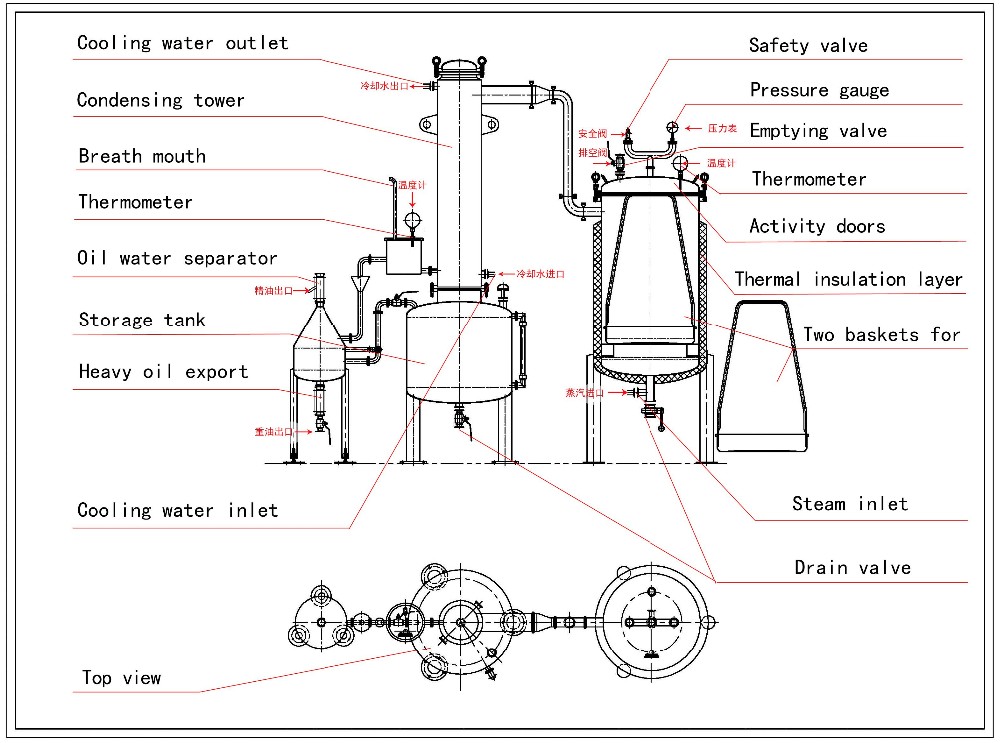

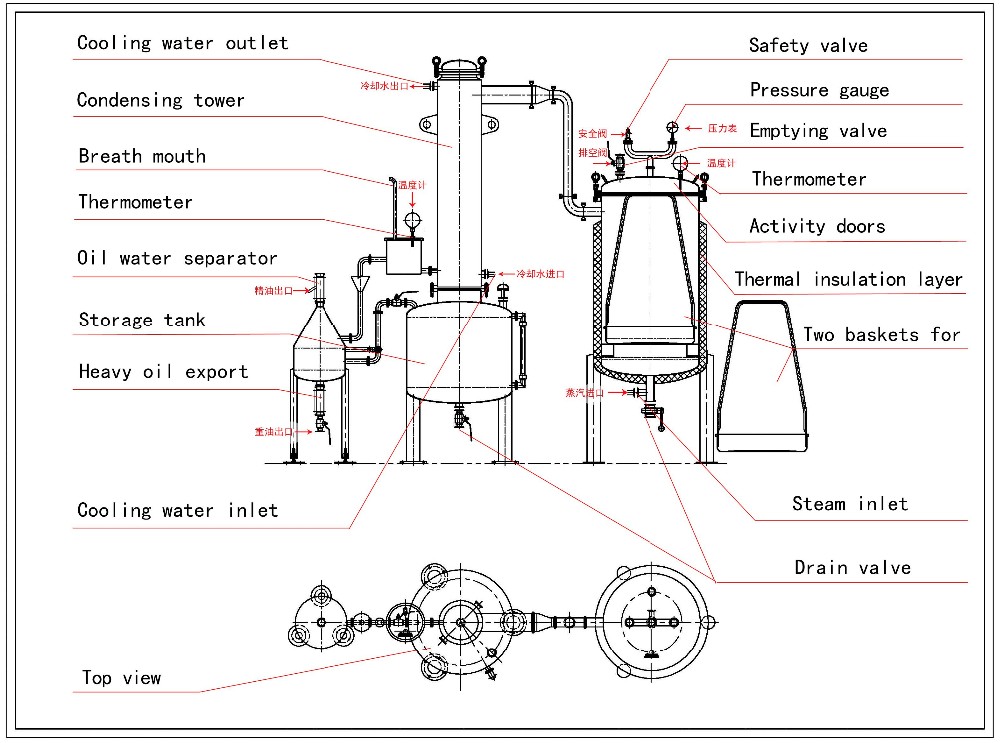

Structure Diagram Of 1000l Essential Oil Distillation Equipment

Structure type: The device consists of inverted vertebral distillation kettle, demister, condensing tower, oil-water separator, double filter, supercharger, material conveyor belt, and essential oil, pure dew collection tank, pure dew storage tank, food-grade pump, and other related pipelines composition. Equipment internal surface polishing Ra≤0.6μm, Outer surface matte treatment Ra≤0.8μm, To ensure that no health dead ends, in line with GMP requirements.

The essential oil distillation equipment can be selected according to the residue of raw materials.

The discharge valve of distillation equipment is very important. Different materials and different distillation methods should be used to select different discharge valves.

Dregs of water distillation, use butterfly valve discharge.

Water distillation (steam distillation) slag discharge, the large diameter pneumatic valve discharge, side manhole slag, hanging basket slag.

Detailed Images

CONTACT US

Send us your enquiries and our representative will answer you accordingly.