1500L Essential Oil Distillation Extraction Equipment

1500L Essential Oil Distiller Product Introduction

Our essential oil extraction equipment, health products, biological drugs, cosmetics, and food. This uses technology and chemical separation, can extract plant components efficiently by steam distillation, have a good effect in collecting essential oil from plants.

Advantages Of 1500l Essential Oil Extraction Equipment

- Advance technology: automatic operation, more convenient and safer when running operation;

- Saving space: needn’t large hoisting equipment for installation and operation;

- High efficiency. Pressure device in the kettle can shorten the distillation time,4-6 hours finish one batch;

- Easy operation. One person can operate this machine easily.

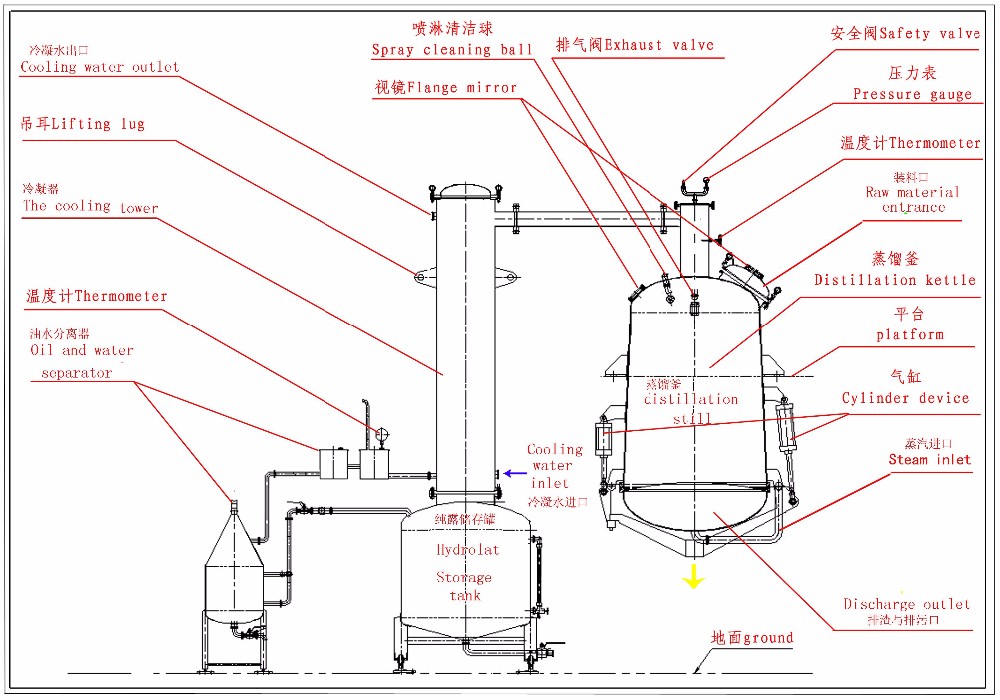

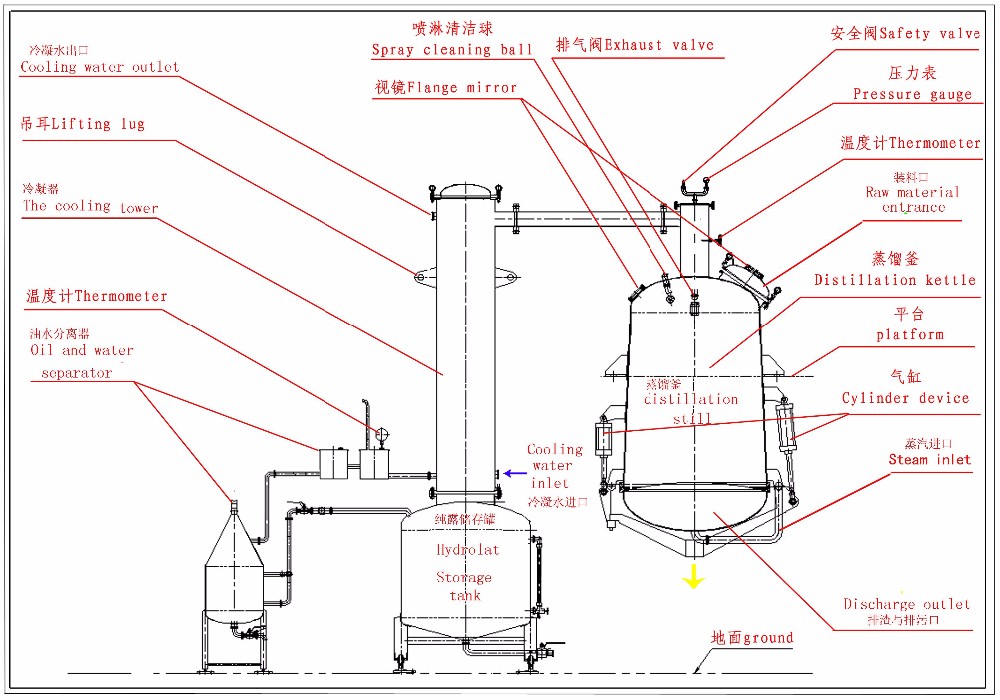

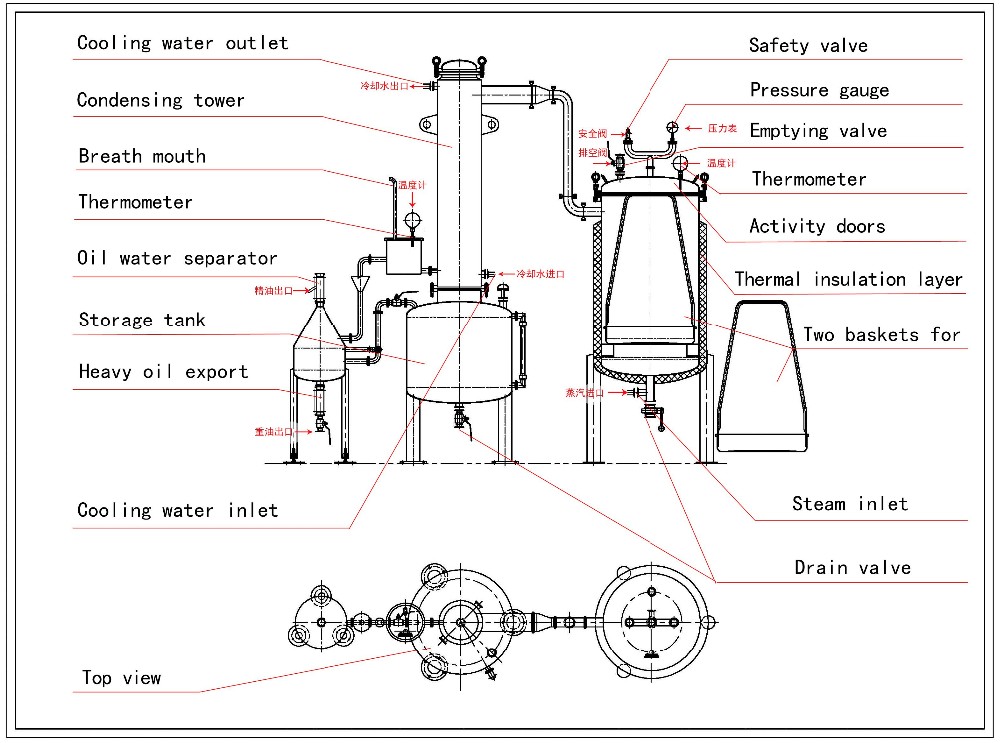

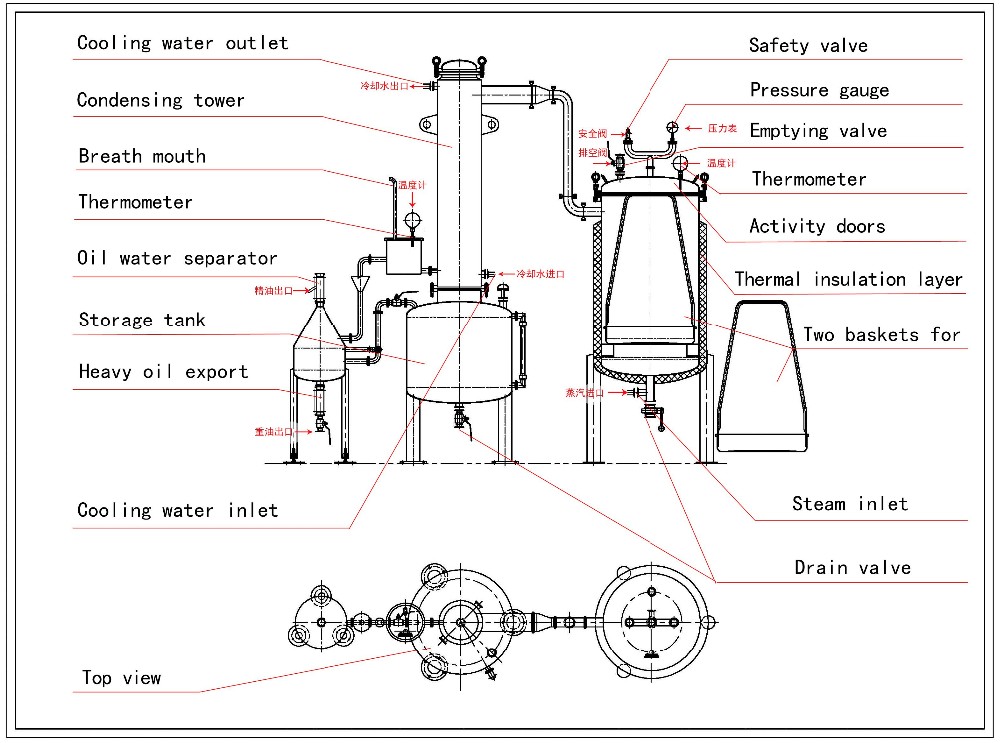

1500l Essential Oil Still Structure Diagram

The device consists of a distillation kettle, material basket, jacket heating layer, insulation layer, demister, condensing tower, re-distillation column, rectifier, oil-water separator, Electric steam boiler, filter, and other related pipelines composition.

Technical Parameters of 1500l Essential Oil Distillation Equipment

| Distillation kettle |

Effective volume 1500L, Steam direct heating, Heat exchange area 6.5m2. Inside: design pressure: 0.09Mpa, working pressure: normal pressure; design temperature:120℃, work temperature≤100℃.Working medium:water; Upper oval head δ= 5mm / S30408, cylinder δ = 5mm / S30408. Slag door: pneumatic rotary slag door, DN1200 |

| Demister | Size Φ300×750,δ=3mm/S30408, The demister contains the internal filter, the top of the demister is set to quick opening. Easy cleaning of the demister. Meet GMP requirements. |

| Condenser |

Vertical condenser. Heat transfer area is greater than 6m2 . Pipeline: designed pressure: normal pressure;working pressure: normal Pressure; design temperature: 100℃, work temperature≤90℃. Working medium:Secondary steam. Length: Φ25×2, material S30408; Shell: designed pressure: 0.3Mpa,working pressure: normal pressure; design temperature: 50℃,work temperature: 15~30℃. Working medium: cooling water. Cylinder δ=3mm / S30408. |

| Pure dew collection tank | made of 304 stainless steel, the capacity of 1 cubic |

| Oil water separator |

the special oil-water separator, stainless steel tank, glass as the cup, tank volume is 40L. Cylinder δ=3mm / S30408. |

| double filter | 120 mesh filter, flow 6.0m³ / h, material for the S30408. |

Application Of Essential Oil Distillation Equipment:

This essential oil distillation equipment is popular, famous, advanced and of top quality in the production of Chinese medicines, health products, biological drugs, cosmetics, and food. This essential oil Distill equipment uses technology and chemical separation, can extract plant components efficiently by steam distillation, have a good effect in collecting essential oil from plants.

Material Information

| Description | Raw material | Description | Raw material |

| Gaultheria procumbens essential oil distiller |

Gaultheria procumbens leaf | Cinnamomum cassia essential oil distiller |

Cinnamomum cassia Cinnamon bark |

| Achillea millefolium essential oil distiller |

Achillea millefolium Flowers and upper branches | Santalum album essential oil distiller |

Santalum album Wood core and root core |

| Cymbopogon nardus essential oil distiller |

Cymbopogon nardus Leaf blade |

Matricaria chamomilla essential oil distiller |

Matricaria chamomilla flowers |

| Pimenta dioica essential oil distiller |

Pimenta dioica seeds | Anthemis nobilis essential oil distiller |

Anthemis nobilis flowers |

| Angelica archengelica essential oil distiller |

Angelica archengelica root | Cinnamomum zeylanicum essential oil distiller |

Cinnamomum zeylanicum Wood core and root core |

| Angelica archengelica essential oil distiller |

Angelica archengelica seeds | Salvia sclarea essential oil distiller |

Salvia sclarea Leaf and upper branch |

| Pimpinella anisum essential oil distiller |

Pimpinella anisum seeds | Eugenia caryophylatta essential oil distiller |

Eugenia caryophylatta bud |

| Arnica montana essential oil distiller |

Arnica montana root | Eugenia caryophylatta essential oil distiller |

Eugenia caryophylatta Leaf |

The essential oil distillation equipment can be selected according to the residue of raw materials.

The discharge valve of distillation equipment is very important. Different materials and different distillation methods should be used to select different discharge valves.

Dregs of water distillation, use butterfly valve discharge.

Water distillation (steam distillation) slag discharge, the large diameter pneumatic valve discharge, side manhole slag, hanging basket slag.

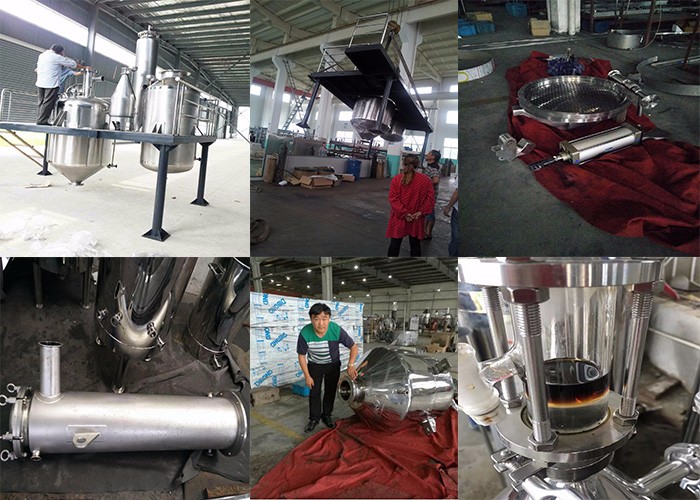

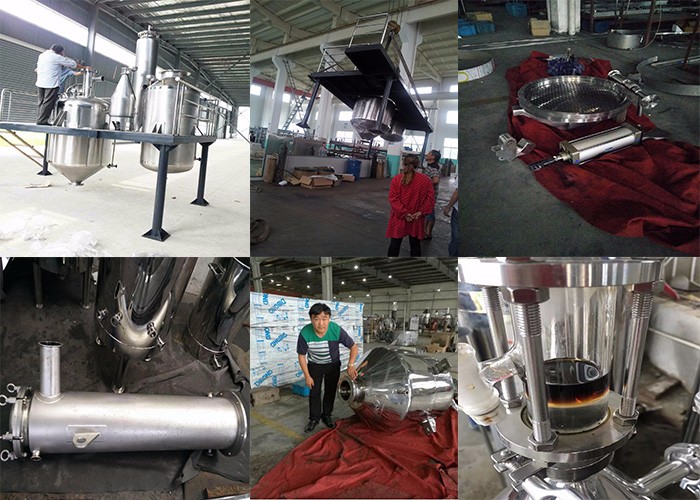

Product Details

CONTACT US

Send us your enquiries and our representative will answer you accordingly.