Isolation & Crystallization Reactor

Isolation & Crystallization Reactor Introduction

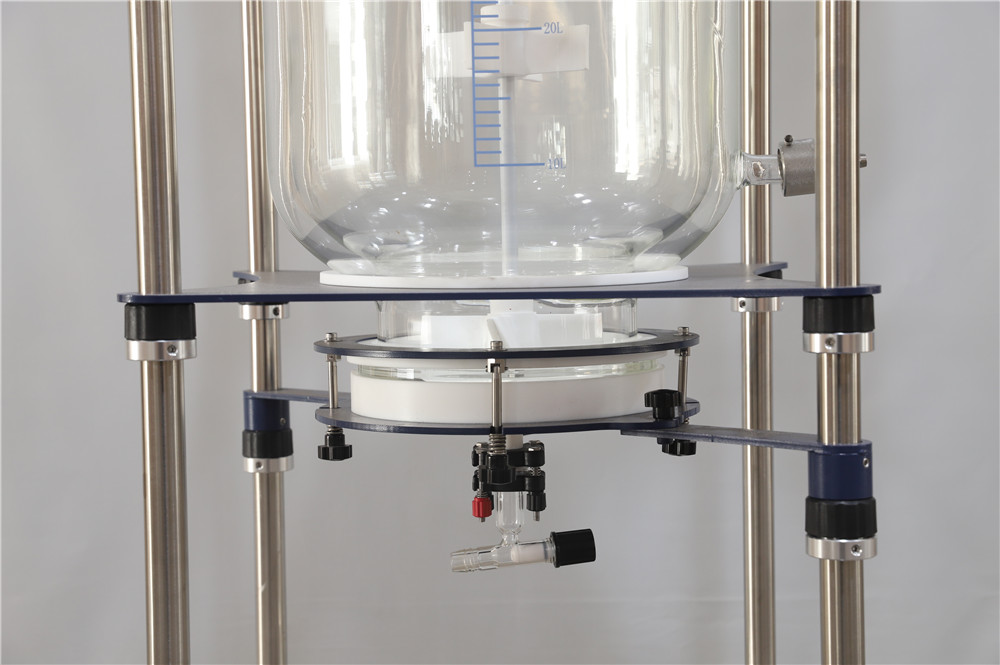

The isolation & crystallization reactor is a commonly used glass reactor for biochemical refinement that combines the functions of the reactor and the filter. It is mainly used in modern fine chemicals,

biopharmaceuticals, scientific research experiments, etc. Our crystallization reactor can crystallize concentrate, distill, reflux, separation, and purification.

Lab1st specializes in botanical refinement equipment. We are an industry leader in the sales and manufacturing of plant oil processing and laboratory equipment.

-

Filter plate pore size can be customized.

-

Food grade high borosilicate glass 3.3 for safety operation

-

Glass & PTFE seals offers fantastic heat, cold, and corrosion resistance

-

Jacket interface can be matched with different heater and chiller

-

Stainless steel supporting framework with lockable casters for mobility and stability.

Technical Parameters

| Model | JGR-20F | JGR-30F | JGR-50F | JGR-100F | JGR-200F | |

| Reaction Capacity (L) | 2~20 | 5~50 | 5~50 | 10~100 | 30~200 | |

| Jacketed Volume (L) | 6 | 16 | 16 | 30 | 40 | |

| Port No. on the Lid | Total (pcs) | 5+1 | 5+1 | 5+1 | 5+1 | 5+1 |

| Stirrer Port | 50# | 50# | 50# | 50# | 60# | |

| Air charging valve | 34# | 34# | 34# | 34# | 34# | |

| Solid feeding Port | 80# Flange | |||||

| Thermometer Tube | DN25 Flar | |||||

| Reflux Separator | 50# | |||||

| Ball Mill Mouth | ||||||

| Condenser Port | 34#, Sprial Condenser | |||||

| Pressure Equalized Funnel | 40#,1000ml | 4O#,2000ml | 4O#,2000ml | 40#,2000ml | 10L | |

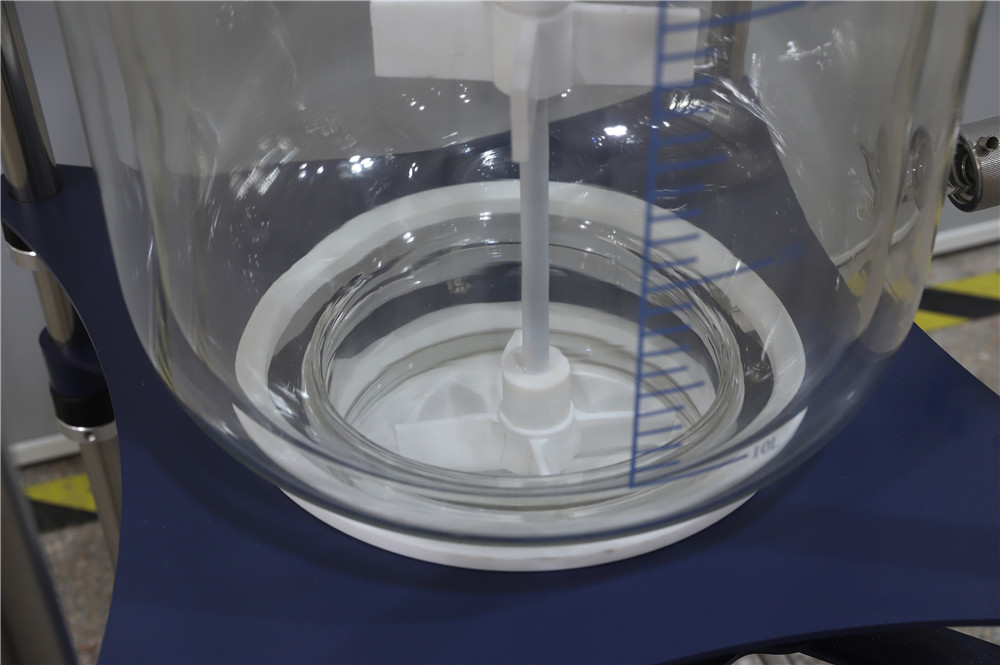

| Fixed Filter Plate | PTFE 1mm | |||||

| Filter Part | Conventional | PTFE Sand Core Filter Plate ( 25 μm) | ||||

| Optional | T-polyester/T-polyester Filter Cloth ( 2 μm) | |||||

| Discharge port | OD:32mm, ID:22mm | |||||

| PTFE Stirrer | Four-blade Type | Four-blade type, Two-layer | Four-blade type, Three-layer | |||

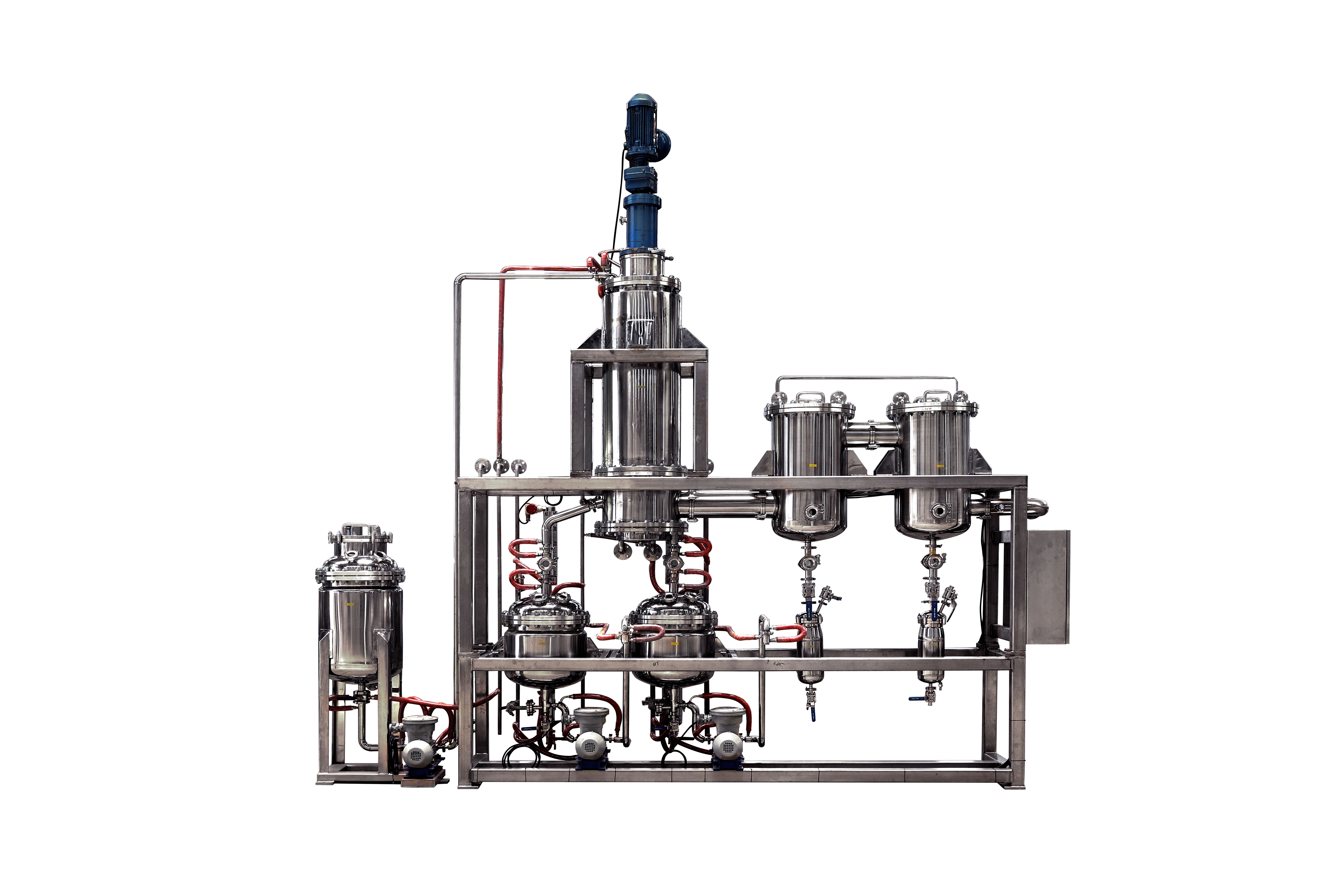

Turnkey Solution:

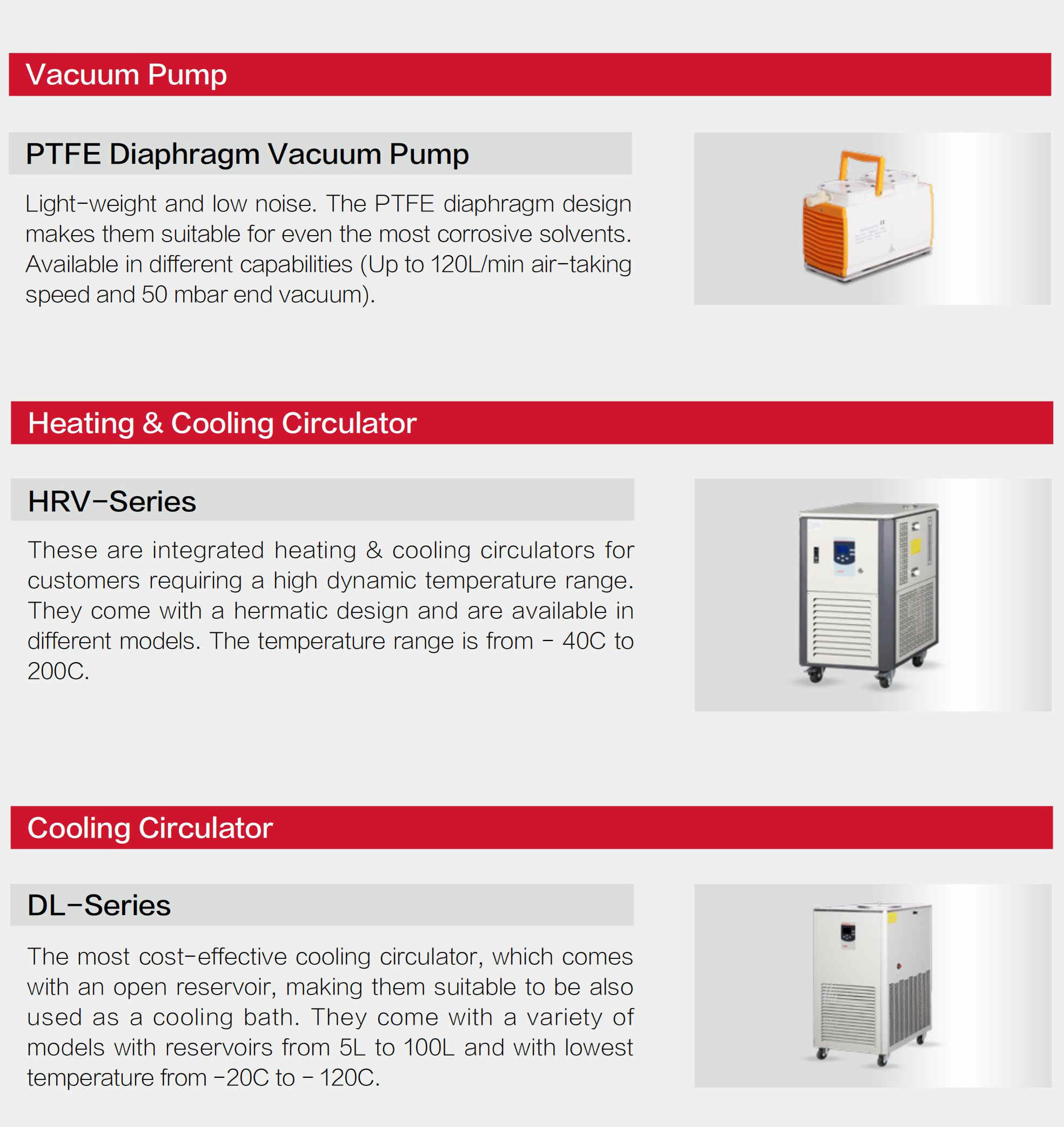

AUXILIARY EQUIPMENTS:

CONTACT US

Send us your enquiries and our representative will answer you accordingly.