Decarboxylation and Fine Evaporation Reactor

Decarboxylation and Fine Evaporation Reactor Machine Introduction

The jacketed glass reactor is becoming an essential piece of equipment for chemical reactions. Highly prized for its versatility and durability, a reactor can perform decarboxylation, winterization,

pesticide remediation, and isolate crystallization. Our glass reactor offers many advantages to processing plant oil. We have specially designed jacketed glass reactor with receiving flask to realize

the decarboxylation reaction with ease-of-operation and efficiency.

Our specializes in botanical refinement equipment. We are an industry leader in the sales and manufacturing of plant oil processing and laboratory equipment.

-

Outstanding heat exchange area.

-

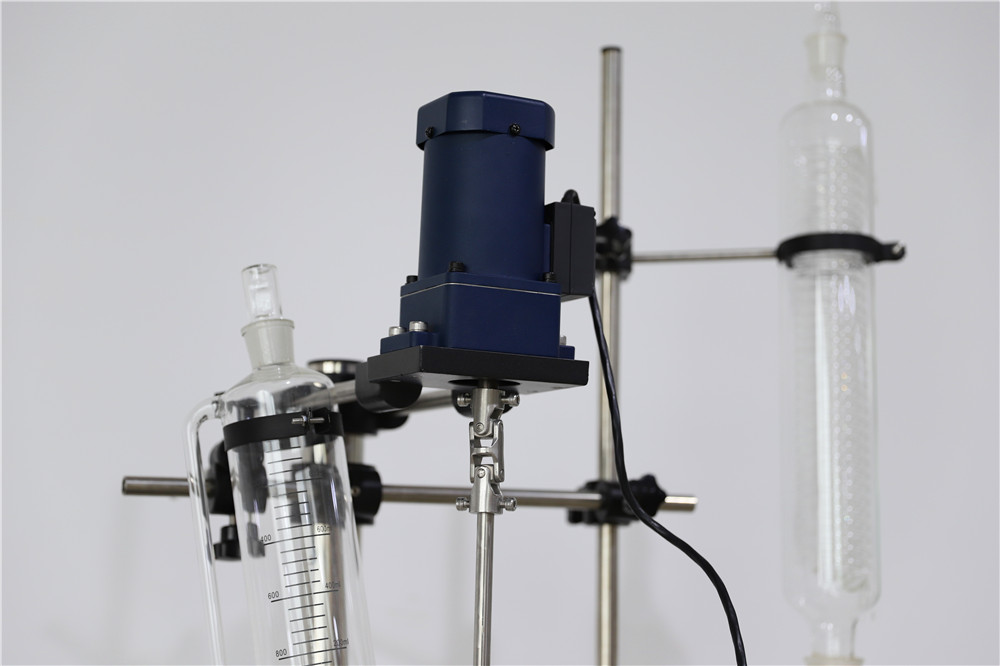

Multi-layer stirring blades offer great torque and high stirring speeds.

-

Food grade high borosilicate glass 3.3

-

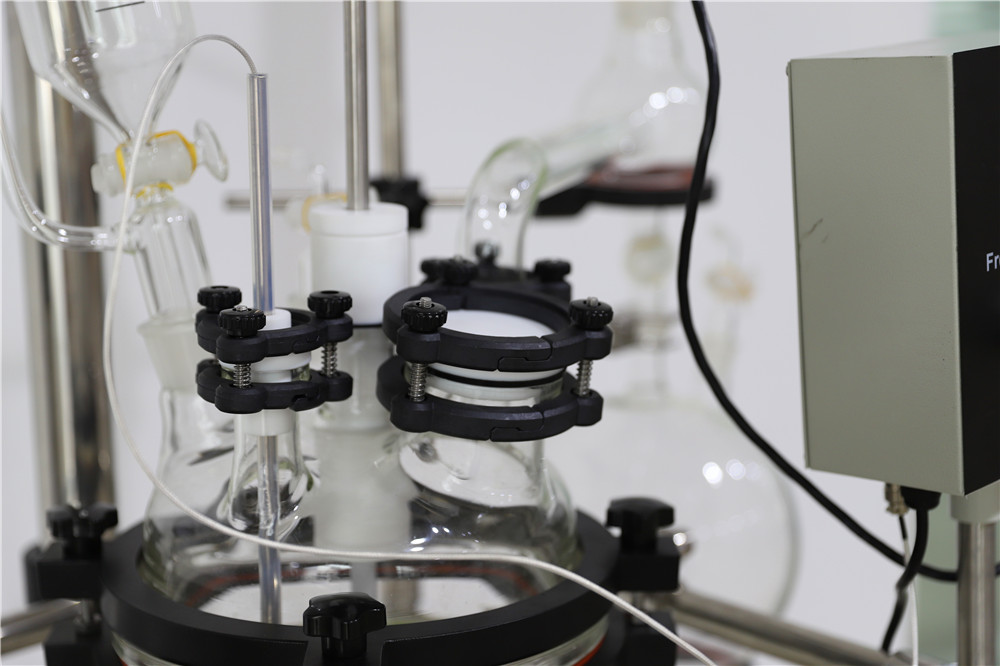

Collection bottle can be customized according to the special needs of customers.

-

Glass & PTFE seals offers fantastic heat, cold, and corrosion resistance.

-

High quality thermal insulation jacket available.

Technical Parameters

| Model | JGR-5L-EVP | JGR-10L-EVP | JGR-20L-EVP | JGR-50L-EVP | JGR-100L-EVP | |

| Reaction Capacity (L) | 5 | 10 | 20 | 50 | 100 | |

| Jacketed Volume (L) | 2 | 3 | 6 | 16 | 30 | |

| Collection bottle volume(L) | 1 | 5 | 5 | 10 | 10 | |

| Port No. on the Lid | Total (pcs) | 4+1 | 5+1 | 5+1 | 5+1 | 5+1 |

| Stirrer Port | 12# | 50# | 50# | 50# | 60# | |

| Air charging valve | 24# | 34# | 34# | 34# | 34# | |

| Solid feeding Port | N/A | 80# Flange | ||||

| Thermometer Tube | 19# | DN25 Flar | ||||

| Reflux Separator | 34# | 50# | 50# | 50# | 50# | |

| Ball Socket Joint | ||||||

| Condenser Port | 34#, Sprial Condenser | |||||

| Pressure Equalized Funnel | 24#,250ml | 4O#,1000ml | 40#,2000ml | |||

| Discharge port | N/A | OD:32mm, ID:22mm | ||||

| PTFE Stirrer | Four-blade Type | Four-blade type, Two-layer | ||||

Turnkey Solution:

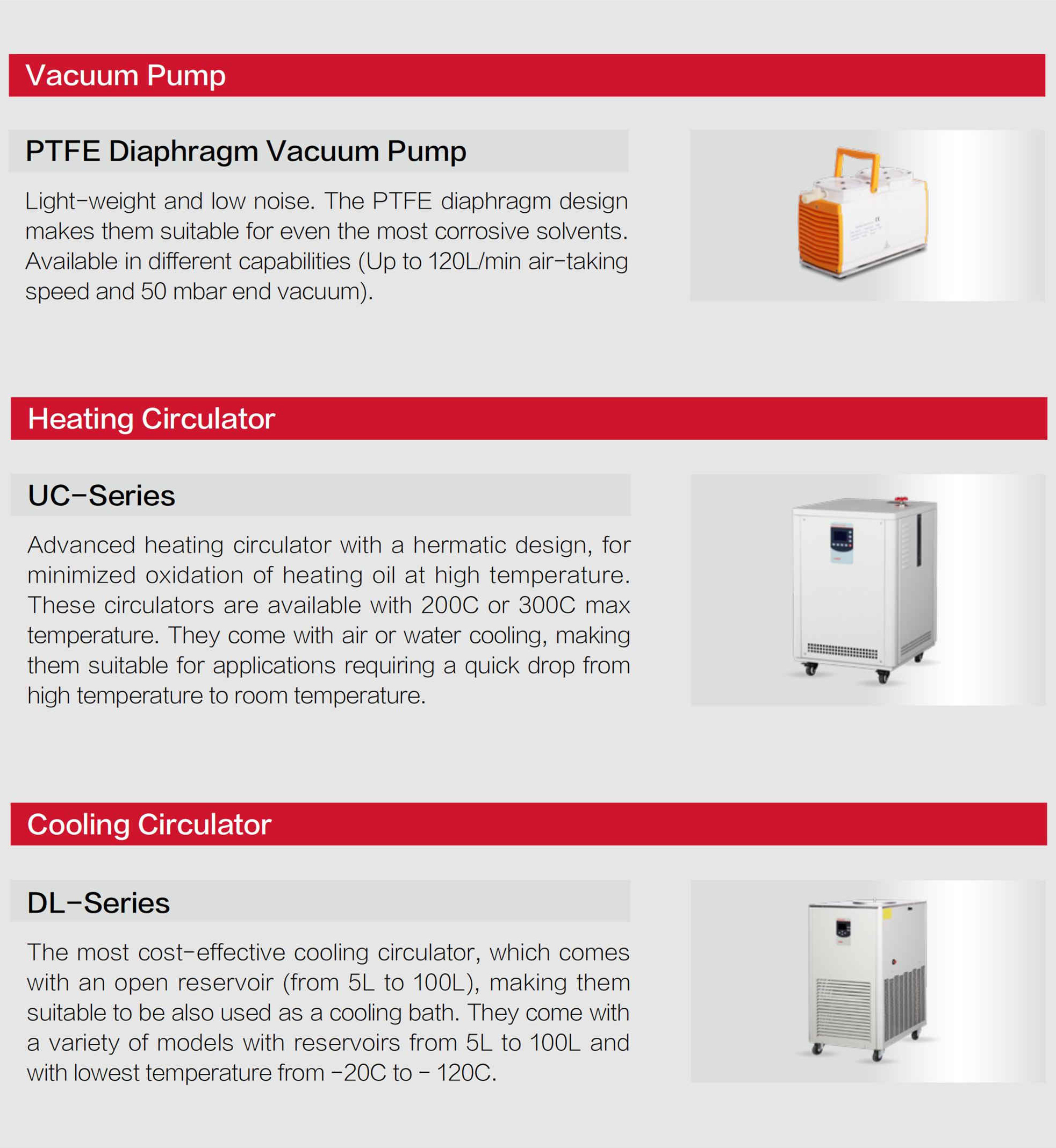

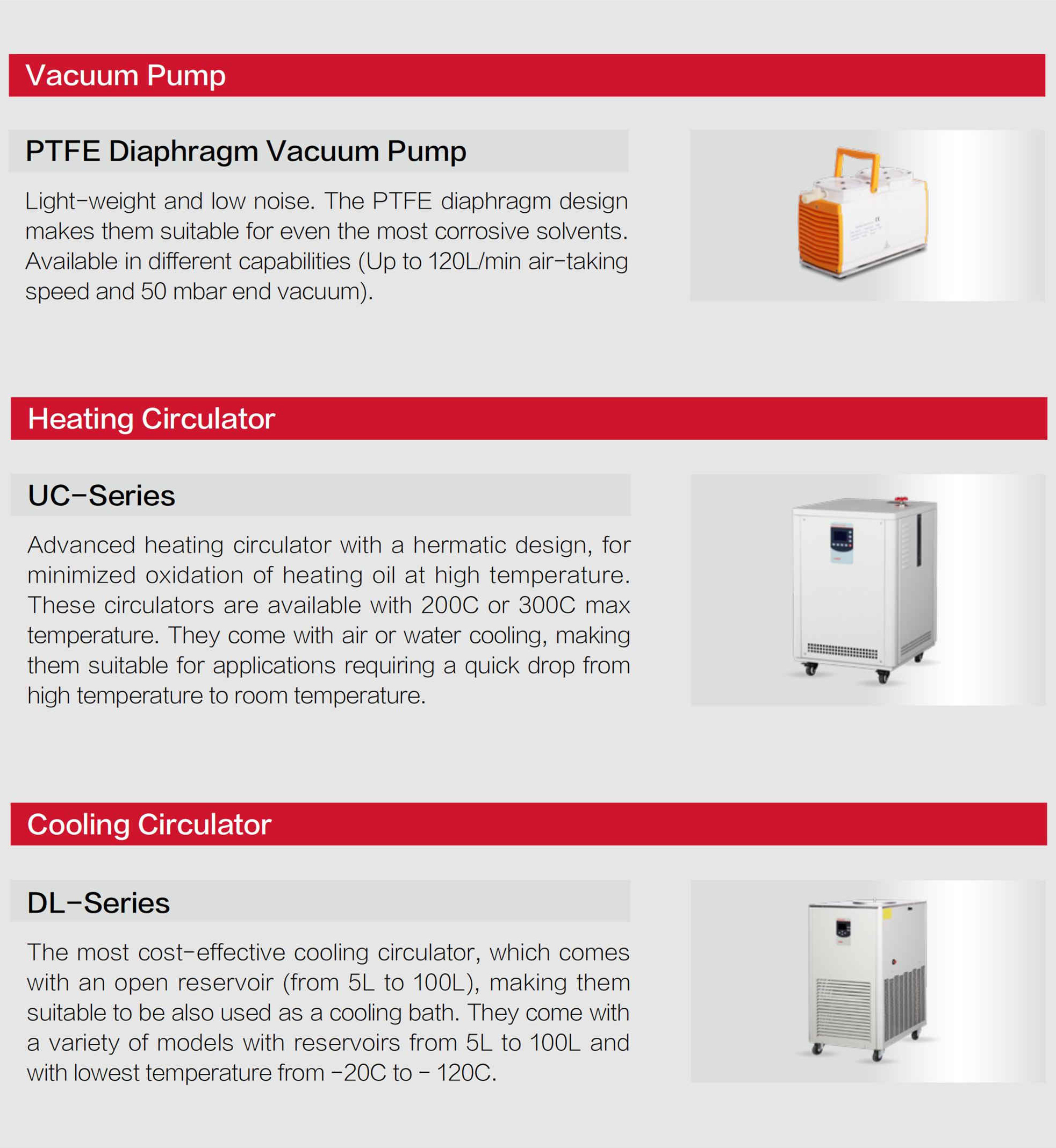

AUXILIARY EQUIPMENTS:

CONTACT US

Send us your enquiries and our representative will answer you accordingly.