1) Distillation: It is the most commonly used extraction method. Distillation technology and distillation method determine the quality of essential oils.

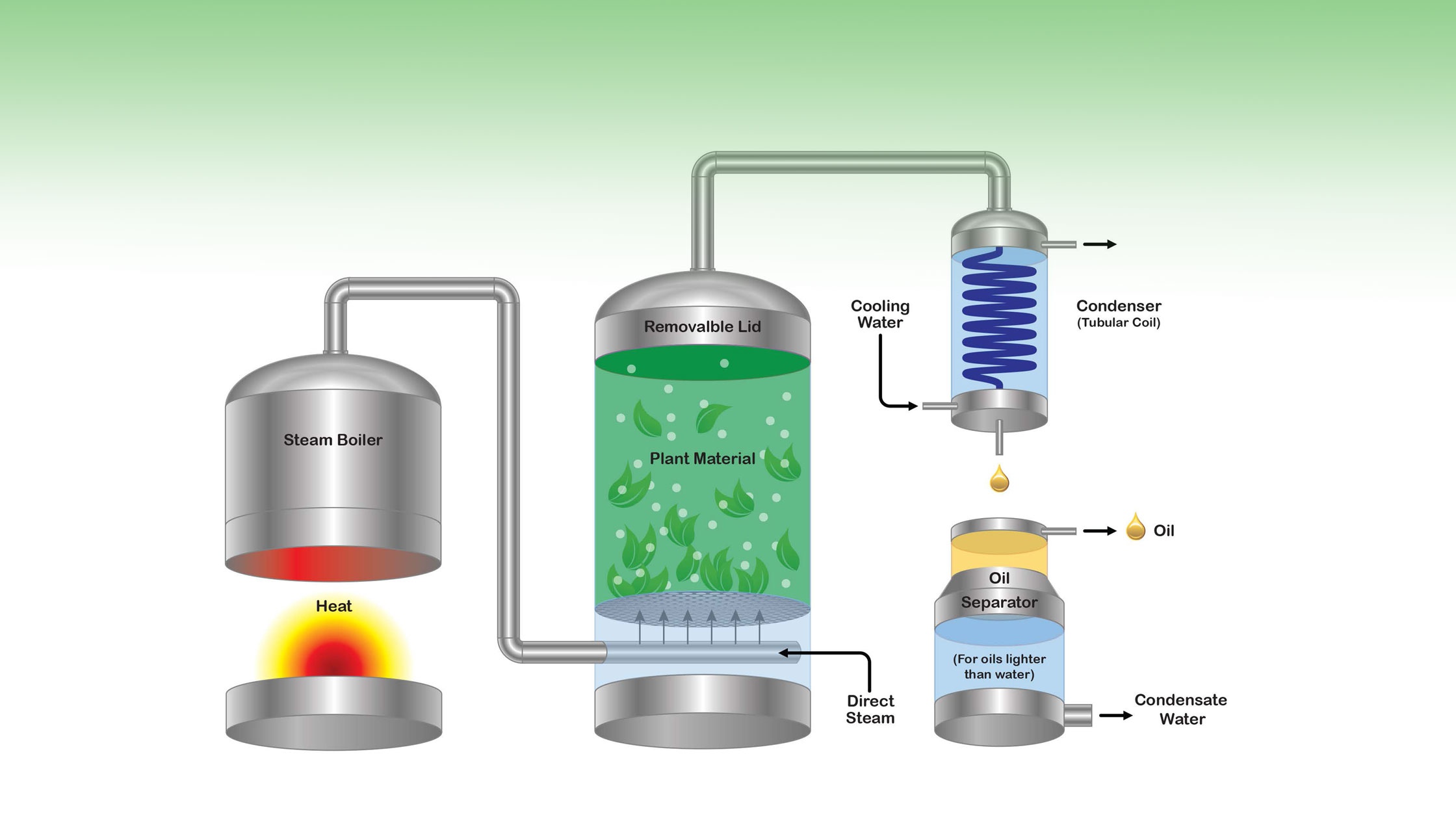

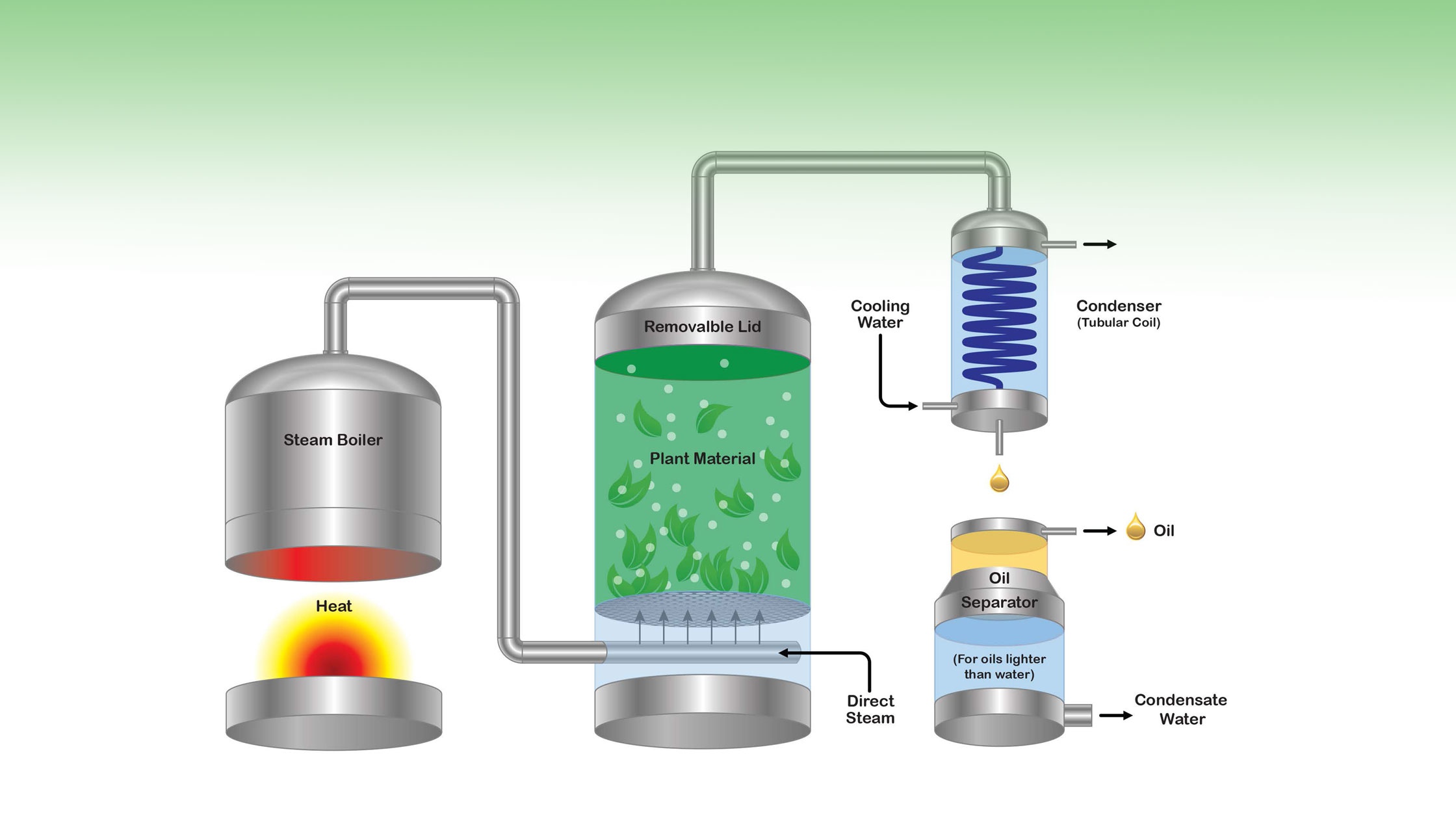

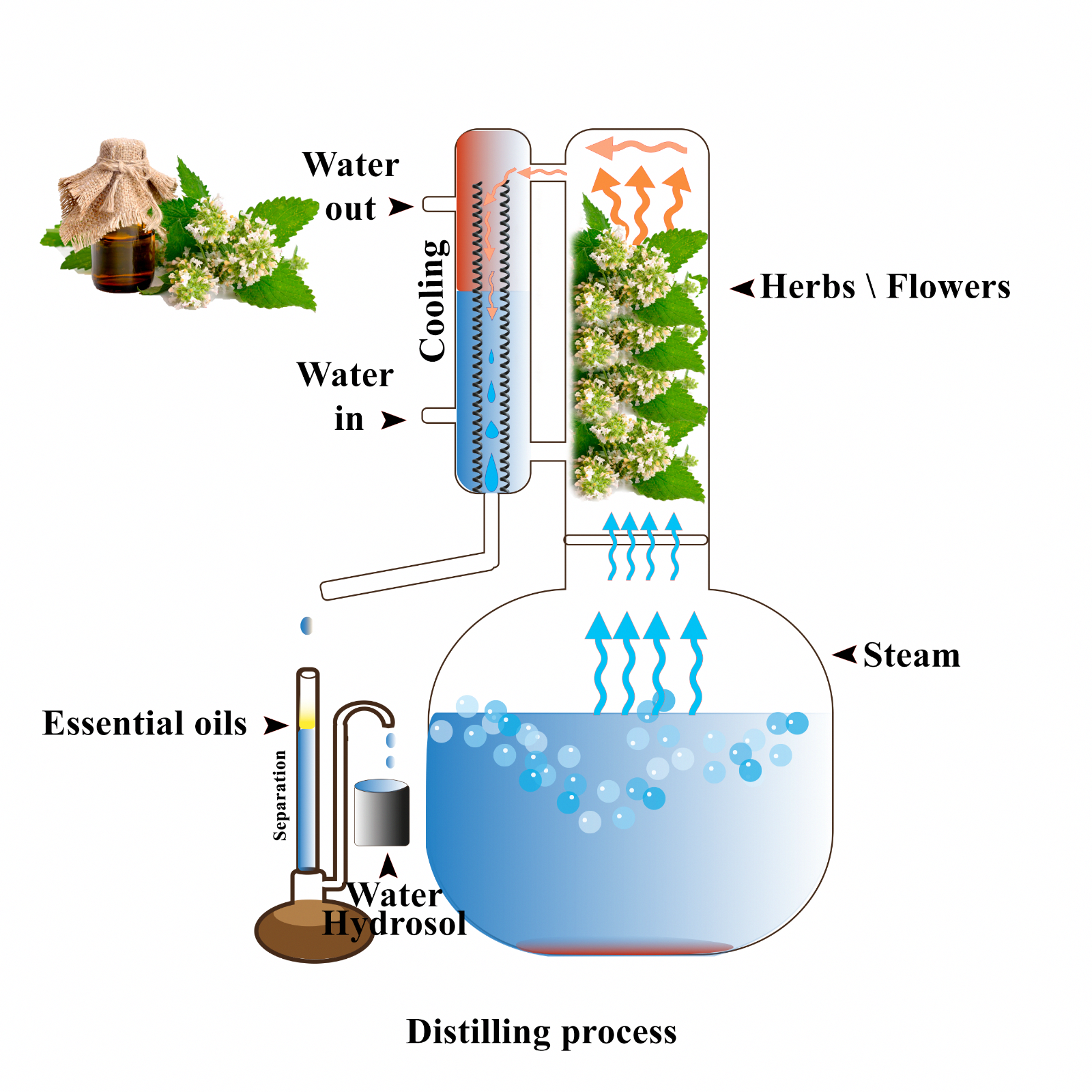

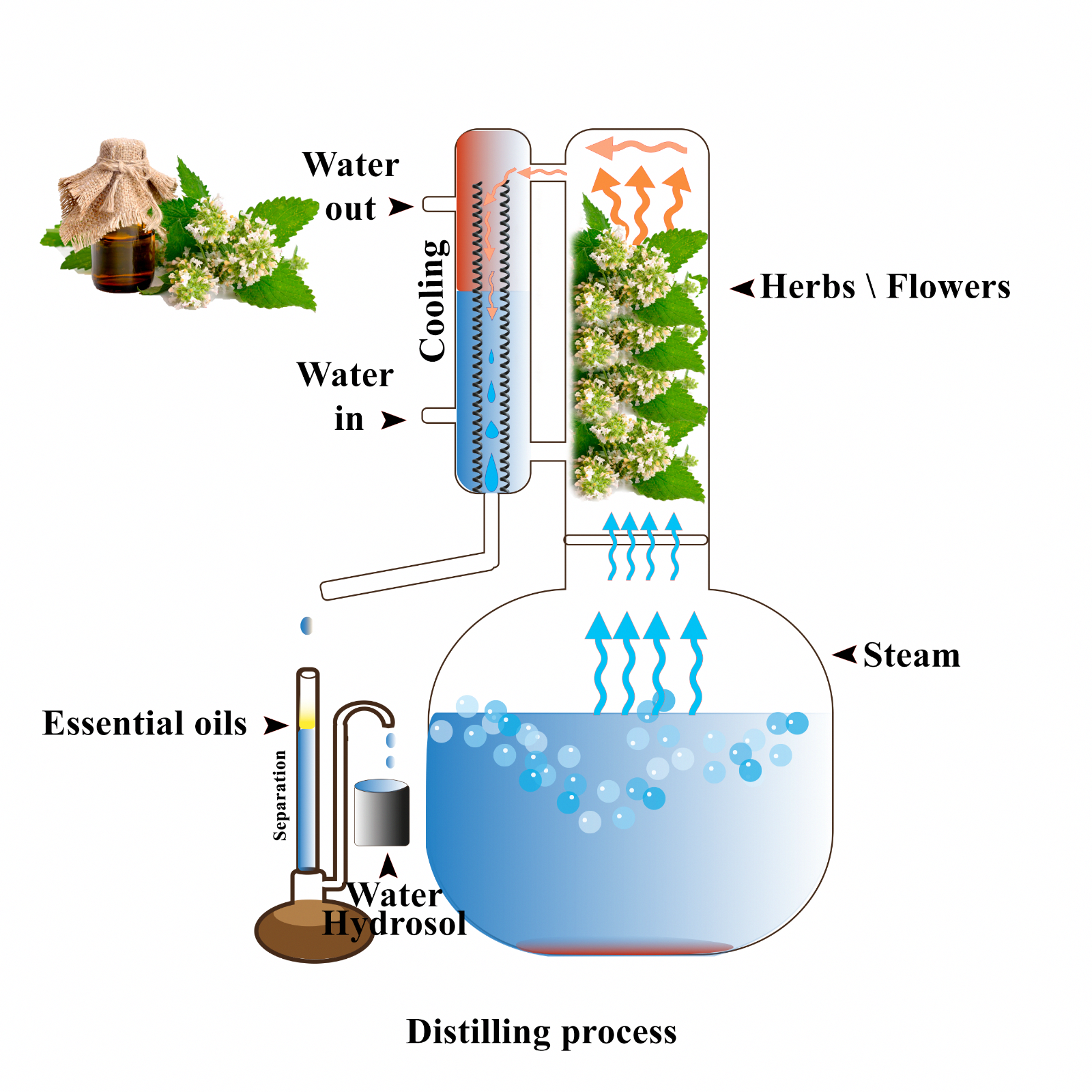

1.1) Steam distillation: It is suitable for plants that are more resistant to high temperatures, usually around 1-48H. Plants are immersed in water vapor, and as the water vapor evaporates upwards, the oil evaporates, and then it is collected through pipes and after the water is cooled, it condenses into liquid. In addition, essential oils are insoluble in water and will gather above the water. Essential oils and condensed water can be obtained through the separator (that is, pure dew, which contains plant trace elements). Such as lavender, rosemary, petitgrain, and other essential oils;

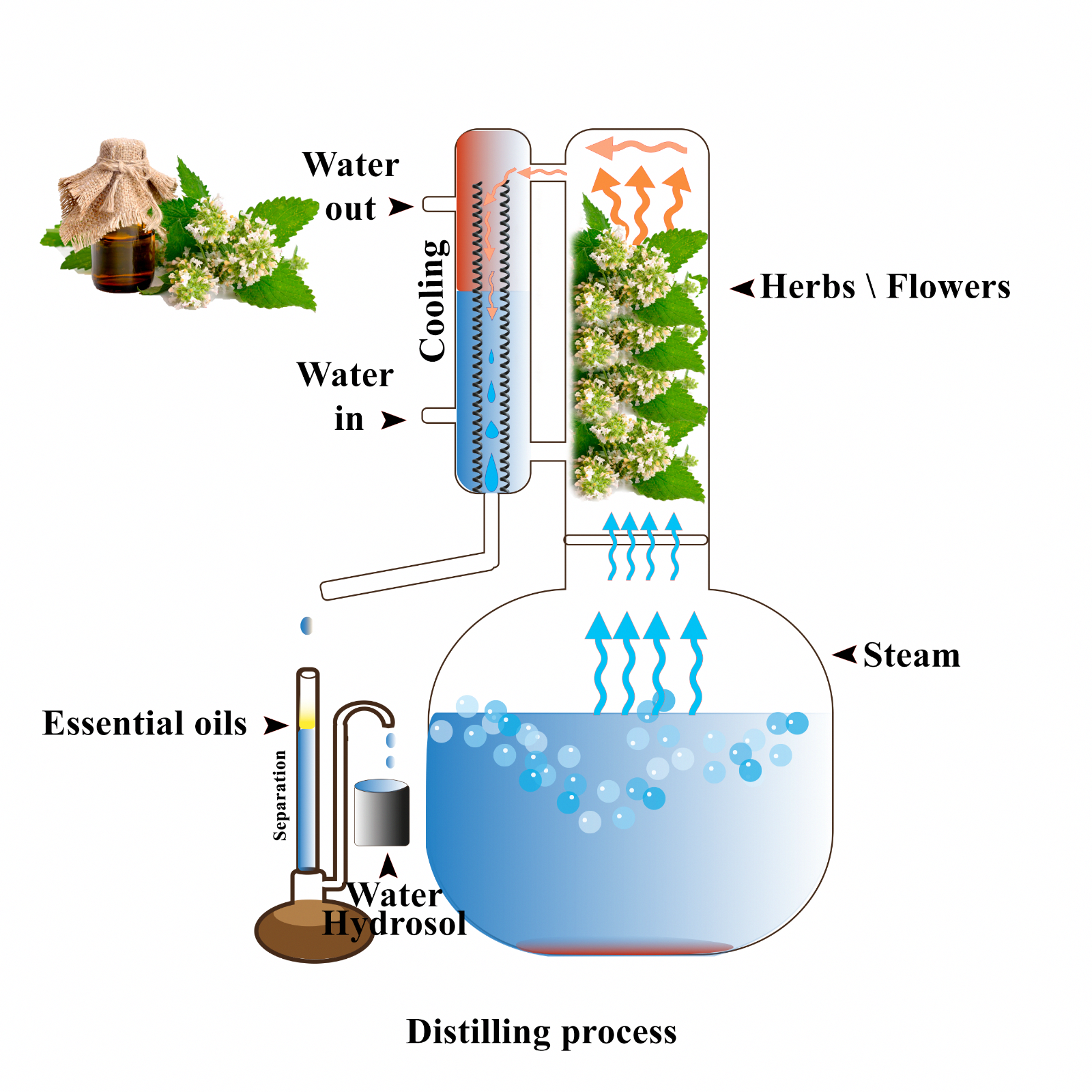

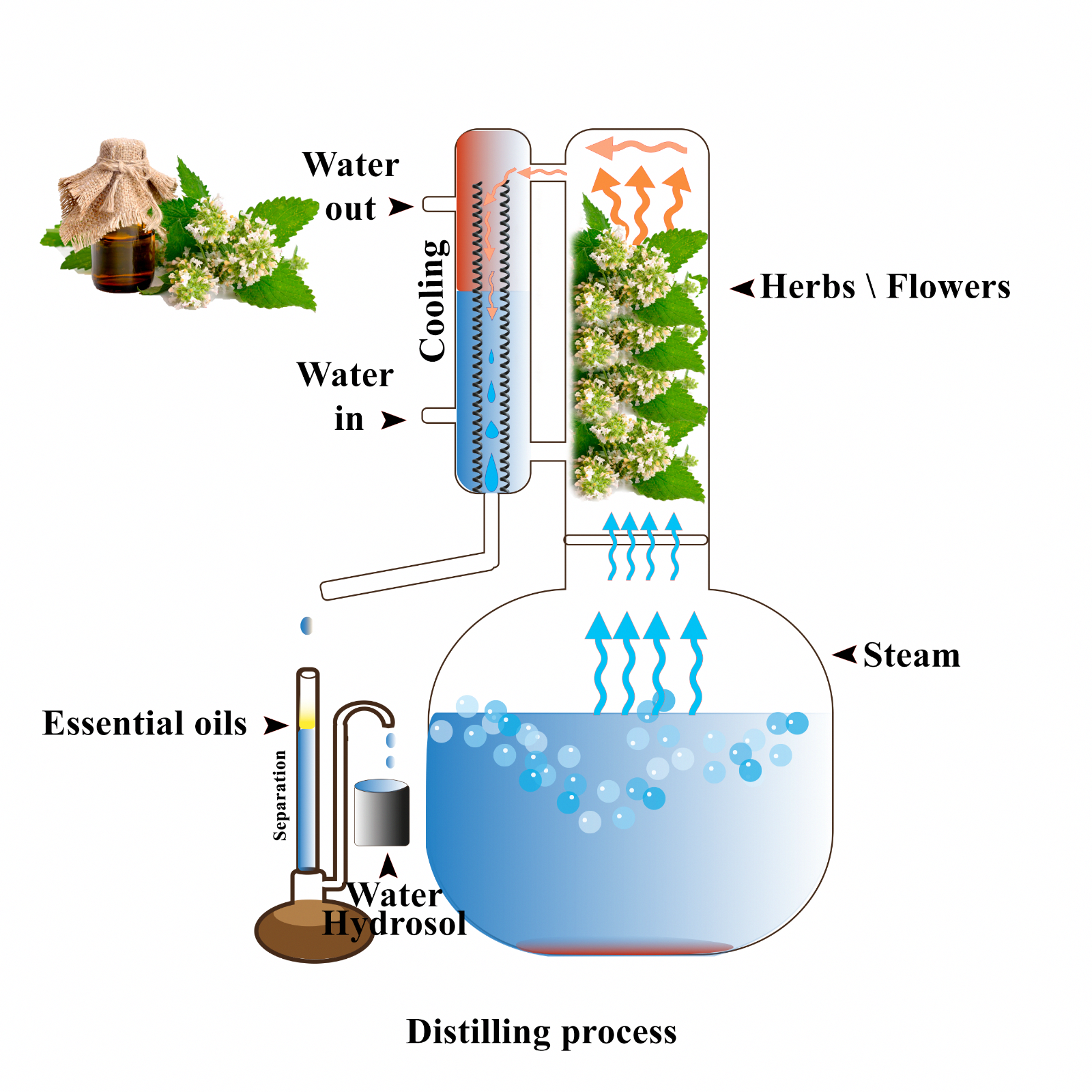

1.2) Water distillation: Because its temperature is often lower than 100°C, it is usually suitable for flower plants, such as neroli, rose and other essential oils. Put the fresh or dried plant raw materials into the distiller, heat from below and send in steam to evaporate the essential oils of the plants. Separate the essential oil and pure dew with a separator;

1.4) Osmotic distillation (Osmotic distillation): mostly used to extract plant rhizomes, woody plants, such as sandalwood, Atlantic cedar, patchouli, etc. By changing the direction of the steam, the steam is forced to press the plant from top to bottom, causing the cell wall to burst to release essential oils. Due to the small amount of steam used and the slow flow rate, the essential oil components can be kept intact, and the extracted essential oils are of good quality, but the technical cost is high, so the popularization rate is not wide;

2) Cold pressing method: It is most commonly used for fruit plants, such as lemon, citrus, bergamot, etc. The squeezing method includes 4 kinds of sponge suction method, bowl punch method, centrifuge separation method, and economic method;

2.1) Among them, the sponge absorption method and the bowl thorn method are ancient methods, which are rare nowadays;

2.2) Economic law (Ecomonic) refers to the essential oils that are separated when squeezing juices, which are cheap but easy to deteriorate;

2.3 ) by centrifuge separation is in the process of pressing the skin with water, after collecting the sap, centrifuge separating the oil out, is a modern common and fruit plants extraction of high value ;

3 ) fat absorption method: A Method for extraction of rare flowers, using oil to absorb the odor molecule, and then extracted with alcohol ” original essence “, for after the alcohol evaporates, leaving that is, the aromatic oils under. Such as jasmine, orange flower. This technology is the predecessor of the solvent ;

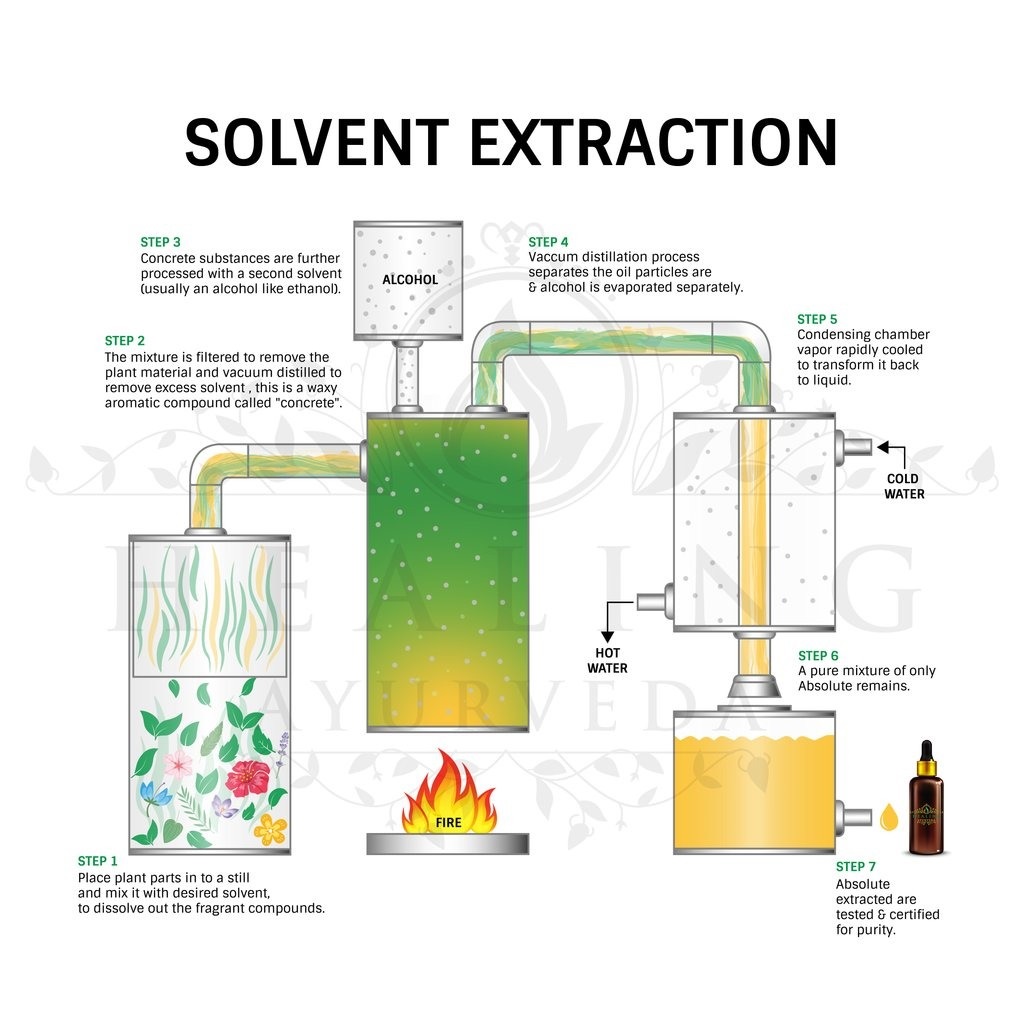

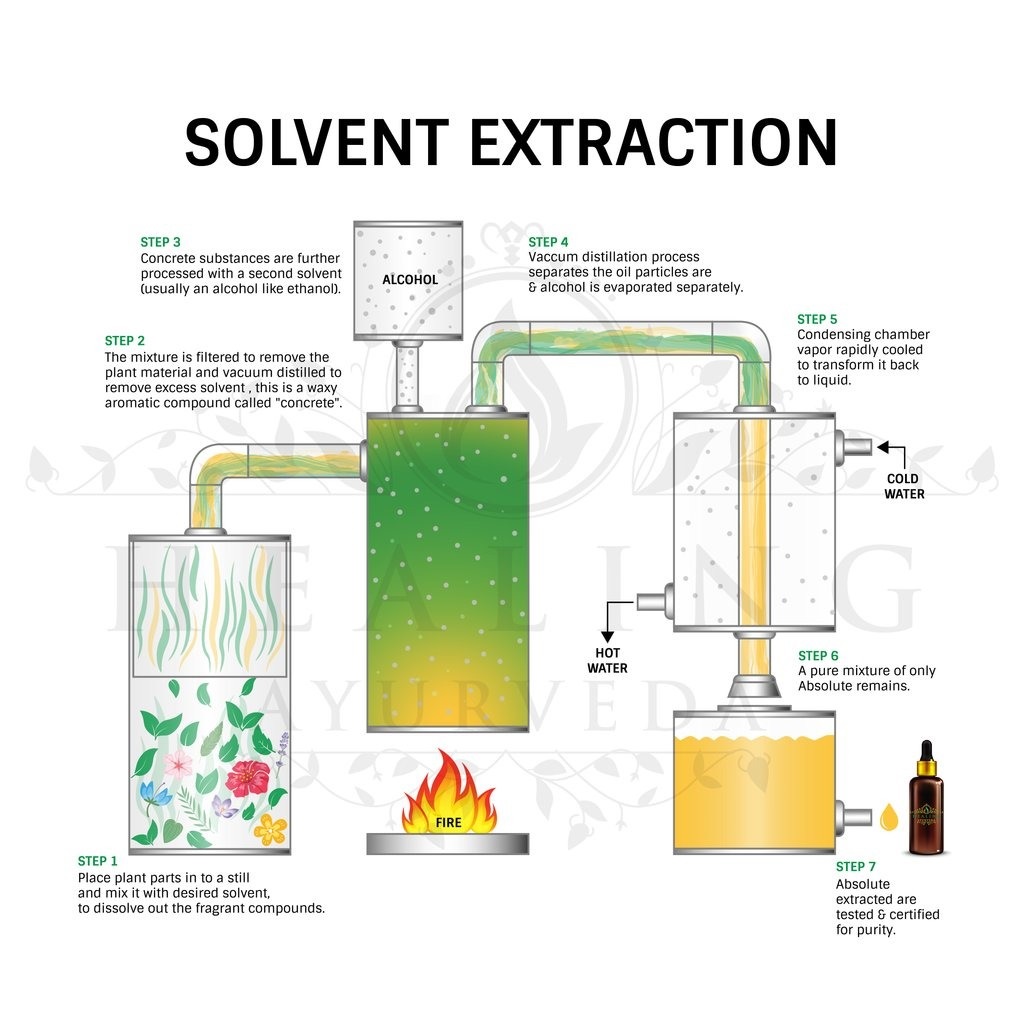

4 ) by Solvent Extraction ( Solvent Extraction ): extract delicate flower and is not suitable for high-temperature distillation extraction. The market generally marked ” absolute ” essential oils. Use solvents such as alcohol and ether liquid butane, repeatedly get in plants, and will contain solvent separation of essential oils, to low-temperature distillation can acquire the essential oils, to replace fat absorption method. Such as cinnamon, benzoin, and so on;

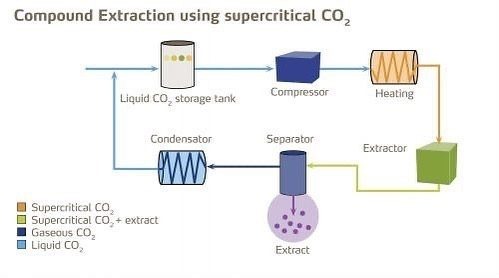

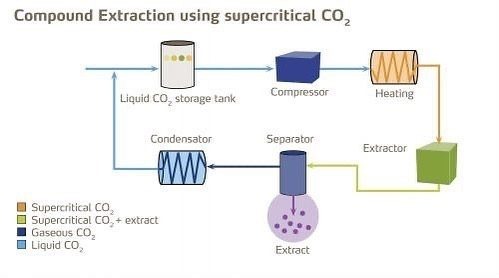

5 ) CO2 extraction: total are conducted at low temperatures, under very high-pressure conditions will be dissolved out of essential oils from plants, scented so there is no heating effects. Due to the extraction time is short, about 10 minutes, there will be no chemical reaction between the solvent and flavor. In addition, for devices large and expensive, only for precious essential oils and products marked with the CO2 ;

6 ) hydraulic extraction: Is derived from steam distillation. The steam produced and infiltration down from above the plant, its advantages are lower and shorter gas steam, so you can increase the production of essential oils and essential oil aromas and colors are good ;

7 ) Ultrasonic Extraction: the latest methods of extraction, the developed countries in science and technology applications. It used high strength, high power ultrasound to improve the defects of the traditional solvent extraction, reduce the heat loss caused by the temperature, can be extracted more bioactive substances, essential oils quality very good, high efficiency of extraction ;

8) Infusion method: The flowers are soaked in hot oil to release the essential oil from the plant, and then extracted by filtration. Such as some infused oils, such as calendula, carrot, etc..